Super Low Humidity / Dew Point Industrial Desiccant Wheel Dehumidifier

-

High Light

dry air dehumidifier

,high capacity dehumidifier

,Desiccant Wheel Dehumidifier 2200m3/h

-

DesiccantRotorSweden Proflute

-

InstalledPower33.95kw

-

ProductNameDesiccant Dehumidifier

-

ProcessAirflow2200m³ /h

-

CertificationCE, ISO

-

SupplyAirT=20℃ TL=-65℃

-

Place of OriginHangzhou, China

-

Brand NameFUDA

-

CertificationCE

-

Model NumberZCH-2200

-

Minimum Order Quantity1set

-

Packaging DetailsWooden Case

-

Delivery Time45days

-

Payment TermsT/T, LC

-

Supply Ability10000set/Year

Super Low Humidity / Dew Point Industrial Desiccant Wheel Dehumidifier

Super Low Humidity / Dew Point Industrial Desiccant Wheel Dehumidifier

Quick Details:

Style: double wheel adsorption

Desiccant Rotor: Sweden Proflute

Desiccant: silica gel and molecular sieve composite wheel

Process Airflow: 2200m³ /h

Supply Air Parameters: T=20℃ TL=-65℃

Dehumidifying Efficiency: High

Installed Power: 33.95kw

Power Supply: 380V/3P/50Hz or customized

Certification:CE, ISO9001:2008

Features: economical, energy-saving

Usage: super low humidity control

General Description:

ZCH-2200 Industrial Desiccant Dehumidifier is for air deep drying, which is used for manufacturing spaces and processes that require extremely low humidity levels. It can supply air with dew point less than -60℃ to glove box for the production of lithium batteries.

Specifications:

|

Main Parameters |

|

|

|

Model |

ZCH-2200 |

|

|

Total Process Airflow(Fresh Air) |

2750 m³/h |

|

|

Supply Airflow |

2200 m³/h |

|

|

Parameters of Supply Air |

T=22℃, TL≤-50℃ |

|

|

Regeneration Airflow |

First Wheel: 916 m³/h |

|

|

Second Wheel: 550m³/h |

||

|

Regeneration Temperature |

125-130℃ |

|

|

Regeneration Power |

18kw+12kw |

|

|

The Power of Driving Motor |

0.1kw+0.1kw |

|

|

The Power of Regeneration Fan |

0.75kw |

|

|

The Power of Dehumidification Fan |

1.5kw |

|

|

The Power of Process Blower |

1.5kw |

|

|

Cooling Load |

87.7kw |

|

|

Installed Power |

33.95kw |

|

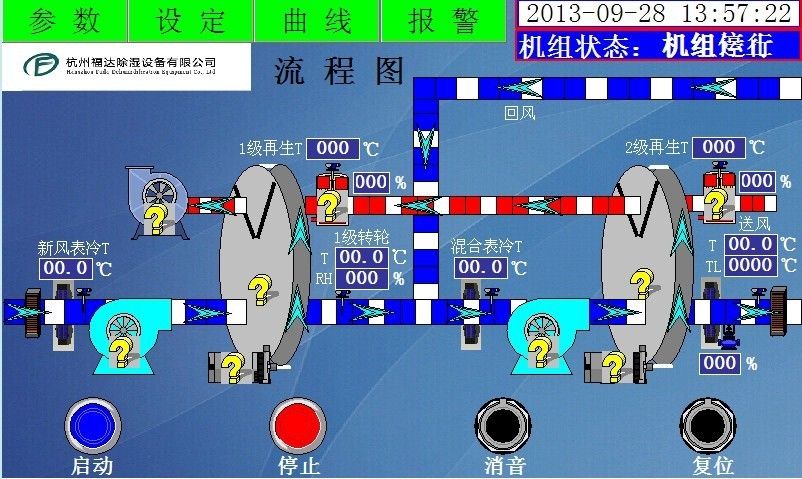

Operating Principles:

Supply Air Stream

Outside air is drawn into the unit using the supply fan. The warm, moist outside air first passes through filters and then the cooling coil where it is cooled. The air then goes through the first desiccant wheel where the air is dehumidified and the temperature is raised. After the medium cooling, the air is further dehumidified by the second desiccant wheel. At last the air is delivered directly to the space or into an existing air handler.

Exhaust Air Stream

Exhaust air is used to provide energy recovery for the desiccant wheel and is drawn into the unit using the exhaust fan. The air filtered and then heated and humidified during the energy recovery process. The air is then heated while passing through the regeneration coil. The heated air removes the moisture that the desiccant wheel adsorbs from the process air stream.

Applications:

- War Industry, Scientific Research, Electric Power Transportation

- Lithium Battery Industry, Biotechnology Pharmaceutical Industry

- Chemical, Daily Chemical Industry, Food Beverage Industry

- Safety Glazing Material Industry, Tyre and Rubber Industry

- Medical Instrument, Vegetables Frozen, Precise Instrument

- Wood Goods, Shipbuilding Painting Industry, Kinds of Storage

Competitive Advantage:

- Sweden Proflute silicon gel wheel

- A totally self contained unit

- Siemens PLC + HMI automatic control system

- Aluminum alloy frame, anti-cold bridge

- Body modularization design, foam injected double wall casing

- Stainless steel drain pan and bottom boards

- Electric or steam heating or convert type can be available.

- All operation parameters can be on-line observed, ensuring the operation reliability

- High temperature safety thermostat cutout

- Electrical interlocking of fan motors, heaters and rotor drive

User Friendly Automatic Interface Control System:

![]()

![]()

We can provide the technical design for dehumidification according to your requirements.