ZCB-50000 Industrial Combined Desiccant Rotor Dehumidifier RH<10%

-

Highlight

20000m3/H Desiccant Rotor Dehumidifier

,Combined Desiccant Rotor Dehumidifier

,Pharmaceutical Desiccant Rotor Dehumidifier

-

Desiccant RotorImport

-

Installed Power56.4kw

-

Product NameDesiccant Dehumidifier

-

Rated Air Flow50000m³ /h

-

CertificationCE, ISO9001:2015

-

Supply AirT=25℃ RH<10%

-

Place of OriginHangzhou, China

-

Brand NameFOUDANCE

-

CertificationCE, ISO

-

Model NumberZCB-50000

-

Minimum Order Quantity1set

-

Packaging DetailsWooden Case

-

Delivery Time60days

-

Payment TermsT/T, LC

-

Supply Ability10000set/Year

ZCB-50000 Industrial Combined Desiccant Rotor Dehumidifier RH<10%

50000m3/h Industrial Combined Desiccant Rotor Dehumidifier RH<10%

Desiccant wheel dehumidifiers are known for their ability to provide extremely low humidity levels, even below the dew point. They can operate in a wide range of temperatures and are often used in applications where refrigerant-based dehumidifiers may not be suitable, such as in cold environments or where precise humidity control is required.

The best way to solve problems at the production of lithium battery products

- How to stop the processes which deteriorate the quality of lithium battery products during production?

- How to minimize idle time of equipment and reduce maintenance costs?

- How to improve long-term storage and increase safety of lithium battery products?

In order to achieve all these goals, it is necessary to reach the optimum humidity during production and storage of products!

Specifications:

| Model | ZCB—50000 |

| Process Airflow(m3/h) | 50000 |

| Requirements | T=25℃, RH≤10% |

| Fresh Airflow(m3/h) | 20000 |

| First Return Airflow(m3/h) | 30000 |

| Second Return Airflow(m3/h) | 0 |

| Rotor Process Airflow(m3/h) | 50000 |

| Rotor Reactivation Airflow(m3/h) | 16600 |

| Parameters of Supply Air | T=18℃, RH≤10% |

| Regeneration Temperature | 120±10℃ |

| Reactivation Steam Consumption (0.4mPa) (kg/h) | 600 |

| Reactivation Fan Power(kw) | 11 |

| Blower Power(kw) | 45 |

| Driving Motor Power(kw) | 0.4 |

| Cooling Load(kw) | 884.2 |

| Chilled Water Consumption(T≤7℃) (T/h) | 152.1 |

| Power Supply | 3P/380V/50Hz(or Customized) |

| Installed Power(kw) | 56.4 |

| ESP(External Static Pressure) (Pa) | 800 |

![]()

These dehumidifiers find applications in various industries such as pharmaceuticals, food processing, electronics manufacturing, chemical industry, and lithium battery factories, among others. They are also used in equipments for specific humidity control needs, although they are less common compared to refrigerant-based dehumidifiers due to their typically higher cost and complexity.

![]()

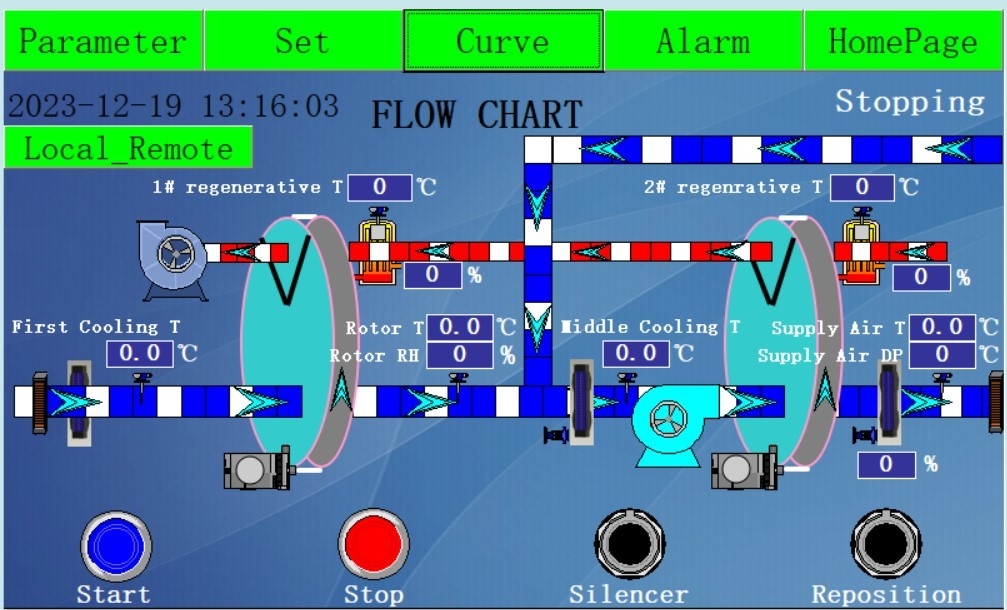

Production Workflow Chart:

![]()

We can create custom dehumidification solutions tailored to your needs. If you're interested in our product, get in touch with us today.