18000m3/h Customized Desiccant Wheel Dehumidifier For Capsule Production Etc.

-

Highlight

Customized Desiccant Wheel Dehumidifier

,Pharmaceutical Desiccant Wheel Dehumidifier

,18000m3/H Desiccant Wheel Dehumidifier

-

Desiccant RotorImport

-

Installed Power16.7kw

-

Product NameDesiccant Dehumidifier

-

Rated Air Flow18000m³ /h

-

CertificationCE, ISO9001:2015

-

Supply AirT≤20℃ RH≤40%

-

Place of OriginHangzhou, China

-

Brand NameFOUDANCE

-

CertificationCE, ISO

-

Model NumberZCB-18000

-

Minimum Order Quantity1set

-

Packaging DetailsWooden Case

-

Delivery Time45days

-

Payment TermsT/T, LC

-

Supply Ability10000set/Year

18000m3/h Customized Desiccant Wheel Dehumidifier For Capsule Production Etc.

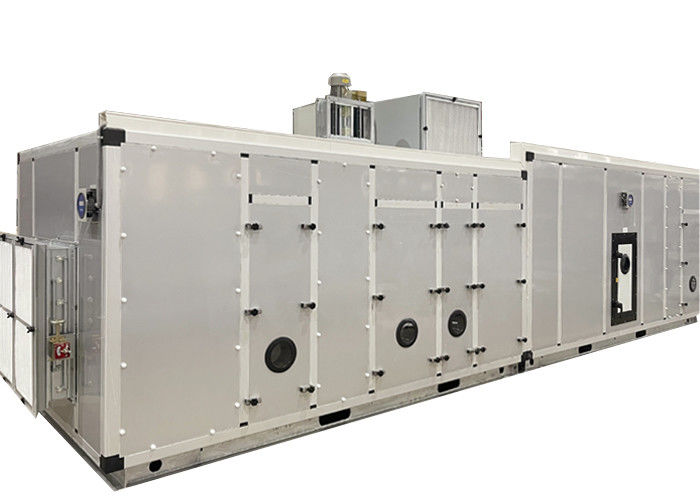

18000m3/h Customized High Efficiency Desiccant Wheel Dehumidifier For Capsule Production Etc.

Desiccant wheel dehumidifiers can be an effective solution for humidity control in capsule production environments. Here are some key points about using desiccant wheel dehumidifiers in this application:

- Principle of Operation:

- Desiccant wheel dehumidifiers use a rotating wheel coated with a desiccant material, typically silica gel or lithium chloride.

- As the wheel rotates, it passes through a process air stream and a regeneration air stream.

- The process air stream is dehumidified as the desiccant material adsorbs moisture from the air, while the regeneration air stream removes the collected moisture from the desiccant.

- Advantages in Capsule Production:

- Desiccant wheel dehumidifiers can maintain extremely low humidity levels, often down to 10-15% RH, which is well within the desired range for capsule production.

- They are highly effective in maintaining stable and consistent humidity levels, even in environments with fluctuating temperatures or high moisture loads.

- The continuous operation of the desiccant wheel allows for uninterrupted dehumidification, ensuring consistent environmental conditions.

- Design Considerations:

- Carefully size the dehumidifier based on the production area's size, moisture load, and desired humidity setpoint.

- Ensure proper air distribution and airflow patterns within the production environment to achieve uniform humidity levels.

- Integrate the dehumidifier with the facility's HVAC system and temperature control to maintain the optimal temperature-humidity relationship.

- Maintenance and Reliability:

- Regular maintenance, such as cleaning the desiccant wheel and filters, is important to maintain the dehumidifier's efficiency and reliability.

- Monitoring the desiccant wheel's condition and replacing it when necessary can help ensure consistent performance over time.

- Redundancy in the dehumidification system, such as having multiple units or backup power, can help mitigate the risk of unexpected failures.

- Integration with Monitoring and Control Systems:

- Connecting the desiccant wheel dehumidifier to the facility's environmental monitoring and control systems can provide real-time data and allow for automated humidity control.

- This integration can help ensure compliance with GMP requirements and facilitate the collection of humidity data for validation and documentation purposes.

Overall, desiccant wheel dehumidifiers can be a robust and effective solution for maintaining the precise humidity levels required in capsule production environments. Proper system design, integration, and maintenance are essential for ensuring reliable and consistent humidity control.

![]()

What is a desiccant dehumidifier?

A desiccant dehumidifier has no compressor and does not use a cold surface to extract the excess moisture from the air. Instead it has a desiccant wheel that absorbs the moisture from the air, in a similar way to a sponge.

When should you use a desiccant dehumidifier?

Desiccant-based systems are more economical than refrigeration systems at lower temperatures and lower moisture levels. Typically, a desiccant dehumidification system is utilized for applications below 45% RH down to 1% RH.

How does desiccant dehumidification work?

Desiccant dehumidifiers use a desiccant material, typically silica gel, which absorbs water vapour from the air. A fan draws air into the dehumidifier and passes it through a section of a slowly rotating wheel which holds desiccant which dries the air.

Specifications:

| Model | ZCB—18000 |

| Process Airflow(m3/h) | 18000 |

| Requirements | T≤20℃, RH≤40% |

| Fresh Airflow(m3/h) | 3600 |

| First Return Airflow(m3/h) | 7200 |

| Second Return Airflow(m3/h) | 7200 |

| Rotor Process Airflow(m3/h) | 10800 |

| Rotor Reactivation Airflow(m3/h) | 3600 |

| Parameters of Supply Air | T=16℃, RH≤40% |

| Reactivation Temperature | 120±10℃ |

| Reactivation Steam Consumption (0.4mPa) (kg/h) | 120 |

| Reactivation Fan Power(kw) | 1.5 |

| Blower Power(kw) | 15 |

| Driving Motor Power(kw) | 0.2 |

| Cooling Load(kw) | 236.3 |

| Chilled Water Consumption(T≤7℃) (T/h) | 40.6 |

| Power Supply | 3P/380V/50Hz |

| Installed Power(kw) | 16.7 |

| ESP(External Static Pressure) (Pa) | 800 |

User Friendly Automatic Interface Control System:

![]()

Air Treatment for Today’s Pharmaceutical Production

![]()

We can make suitbale dehumidifying solution for you according to your requirements, contact us now.